- 公司

- 必威体育app官方下载

- 目录

- 新闻和趋势

- 展览

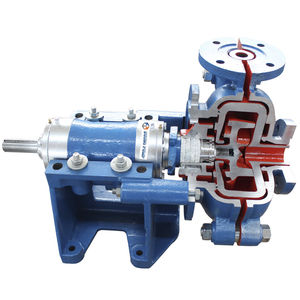

泥浆泵100高铁

对砂

工业水

电

添加到收藏夹”

这种产品比较

特征

- 流体

- 泥浆,用于砂,用于工业用水

- 操作

- 电

- 技术

- 离心

- 域

- 采矿工业,冶金工业,海洋应用

- 流体规范

- 对磨料流体

- 其他特征

- 单级、重型

- 流

-

最小值。120 m³/h (4,237.76 ft³/h)

260 m³/h (9,181.8133 ft³/h)

马克斯。280m³/h (9,888.1067 ft³/h)

- 压力

-

最小值。1 bar (14.504 psi)

4 bar (58.015 psi)

马克斯。6 bar (87.023 psi)

- 头

-

最小值。09年10米(32)

40米(131 02”)

马克斯。50米(164 00”)

- 权力

-

最小值。2.2 kW (2.99 hp)

55 kW (74.78 hp)

马克斯。60 kW (81.58 hp)

描述

渣浆泵是一种离心泵,专为矿山、冶金、洗煤、污水处理、电厂、疏浚等场合泵送含固体颗粒液体而设计。化工、石油等行业的高铁浆泵采用橡胶衬里设计。结构与HS型泵类似,主要区别是耐磨件材质。易损件采用天然橡胶SR26、SR55、SR33制成。解决特殊的坏血病工作条件。为了在磨损寿命内保持高效率,这种类型的泵通常用于工艺装置输送,腐蚀性和腐蚀性湿废物,回收洗涤装置,矿物处理,矿物回收和化学处理装置。特点:轴承组件——大直径轴,短外伸,最大限度地减少挠度,有助于延长轴承寿命。只需要面粉通过螺栓,以保持筒式外壳在框架。尾管—易于更换的尾管采用螺栓连接,而不是粘接,与套管积极连接,易于维护。硬金属内衬完全可与压力模压弹性体互换。所有尾管连接处的弹性密封环。 Impeller---Front and rear shrouds have pump out vanes that reduce re-circulation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. Throat bush---Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Specification ◆ Size: 1”-14” ◆ Capacity: 10-3200 m³/h ◆ Head: 10-50 m

目录

这个产品没有目录。

查看石家庄三博泵业有限公司所有产品目录

0/10的必威体育app官方下载乘积比较