- 公司

- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览

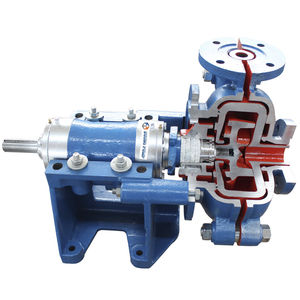

泥浆泵250年hs-st

离心

工业

用于废水处理

添加到收藏夹

比较这个产品

特征

- 流体

- 泥浆

- 技术

- 离心

- 域

- 工业,用于废水处理,用于采矿业,冶金工业

- 应用程序

- 脱水,用于脱硫

- 材料

- 硬质合金

- 流体规范

- 磨料流体

- 其他特征

- 单级,水平安装,重型,悬臂式

- 流

-

最小值。936 m³/h (33,054.52805 ft³/h)

马克斯。1980 m³/h (69,923.04011 ft³/h)

- 头

-

最小值。7米(22'11")

马克斯。68米(223'01")

- 权力

-

560千瓦(761.39马力)

描述

浆液泵是一种离心泵,专为矿山、冶金、洗煤、污水处理、电厂、疏浚等输送含有固体颗粒的液体而设计。HS系列泵专为连续泵送高磨蚀性,高密度浆料而设计,维护要求最低,卧式离心泵将在其部件的磨损寿命内保持高效率。橡胶和金属内衬泵具有径向分成两半的套管。最小的套管螺栓减少了维护,最大限度地减少了停机时间。特点:轴承组件-大直径轴,短悬挑,最大限度地减少挠度,有助于延长轴承寿命。只有面粉通过螺栓需要在框架中保持筒式外壳。衬管—易于更换的衬管通过螺栓固定在套管上,而不是粘接,便于维护。硬质金属衬垫与压力成型弹性体完全可互换。所有衬管接头的弹性体密封圈。叶轮——前后护罩有泵出叶片,减少再循环和密封污染。 Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. Throat bush---Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Specification: Size range (outlet) 1" to 18" 25 mm to 450 mm Capacities to 22,000 gpm to 5,000 m³/hr Head to 240 ft to 73 mt

目录

没有这种产品的目录。

查看所有石家庄孙博水泵有限公司的产品目录