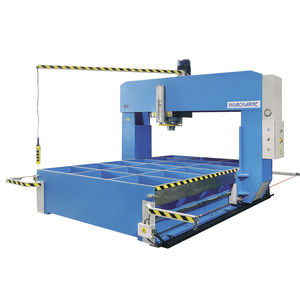

电动压R系列

冲压

拉深

切割

添加到收藏夹”

这种产品比较

特征

- 操作

- 机动化的

- 函数

- 冲压、拉深、切割

- 结构

- 下行程

- 其他特征

- 为生产、双动

- 开放

-

250毫米,300毫米,500毫米(10英寸)

- 力

-

马克斯。4982 kN

最小值。797.1 kN

描述

专门设计来完成涉及拉深,冲压,模切,成型的工作。它由一个电焊结构完全由S355JR钢。它们在结构焊接过程的最后被稳定和加工。这些型号配备了一个机械化的下和上C45E钢表与DIN-650槽。上表通过四个圆柱形横向导轨和免维护的减摩双金属帽确保了完美的对准。调整上表的位置和速度的变化是从一个三面面板控制。气缸是双作用与铬柱塞和免维护的抗磨导轨。双速机动液压单元,具有自动高速熄火功能。它装有一个气缸减压阀。一个压力调节器放置在前面的部分作为标准,允许调节最适当的压力,为每一种压。 Pressure lower than 320 bar. Glycerin gauge with reading in tonnes. The control panel features a switch enabling the user to select the desired type of work in a manual, semi-automatic or automatic position and a switch to select either the fast speed or slow speed. Electrical and hydraulic manoeuvres are redundant and self-controlled. They incorporate an additional safety block and self-control devices for manoeuvre and safety. It includes the verification and certification of the correct operation and the safety distance for the photocells. Operation is carried out by low voltage electric pedals. They allow the installation of a hydraulic cushion or a hydraulic ejector.

目录

液压机HIDROGARNE

32

页面