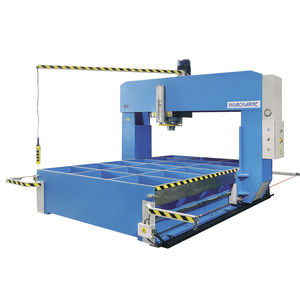

液压机CD系列

冲压

拉深

切割

添加到收藏夹”

这种产品比较

特征

- 操作

- 液压

- 函数

- 冲压、拉深、切割、压花

- 结构

- 向下的,"

- 其他特征

- 为生产、双动

- 开放

-

250mm(10英寸)

- 力

-

498.2 kN, 797.1 kN, 996.4 kN, 1,494.6 kN

描述

专门设计来完成涉及拉深,冲压,模切,成型的工作。它由S355JR钢的电焊结构组成。它们在结构焊接过程的最后被稳定和加工。他们配备了一个机械化的下C45E钢表与DIN-650槽。气缸是双作用与铬柱塞和免维护的抗磨导轨,配有可互换的压盘,以避免柱塞的恶化,并在末端加工,以适应工具,模具和基体。以毫米正面和冲程终点为标准的反转向气缸,使我们能够方便地调节气缸冲程。电动2速液压单元具有自动快速断开。它包括一个气缸减压阀。在侧边放置一个压力开关作为标准,可以为每种压力调节最合适的压力信号。液压压力低于320 BAR。 Glycerin gauge with reading in tonnes The control panel features a switch enabling the user to select the type of work in a manual or semi-automatic position and a switch to select either the fast or slow speed. Electrical and hydraulic manoeuvres are redundant and self-controlled. They incorporate an additional safety block and self-control devices for manoeuvre and safety. Operation is carried out by two-hand push button with level IV security module. They allow the installation of a hydraulic cushion or a hydraulic ejector.

目录

液压机HIDROGARNE

32

页面

0/10的必威体育app官方下载乘积比较