- 公司

- 必威体育app官方下载

- 目录

- 新闻和趋势

- 展览

热处理炉如果系列

退火

扶轮反驳

气体

添加到收藏夹”

这种产品比较

特征

- 函数

- 热处理、退火

- 配置

- 扶轮反驳

- 热源

- 气体

- 大气

- 控制气氛,真空

- 能力

-

10升、40升、75升、120升、260升(2.6加仑)

- 最高温度

-

600°c, 900°c, 1100°c(1112°f)

描述

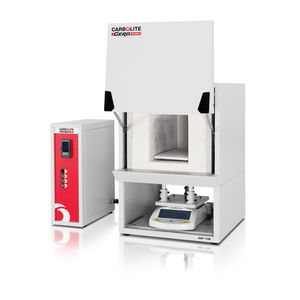

GLO退火炉的特点是具有高度对称的加热元件的真空紧馏器。加热元件是CrFeAl,也被称为APM,并嵌入在陶瓷纤维绝缘体中。在热处理之前,GLO通常配备一个真空抽吸系统来降低氧气水平。为了确保最低的污染水平,几个周期的真空和氮吹扫发生,以创造一个纯净的气氛在甑。真空辅助循环是远远优于简单的流动氮气通过蒸馏釜,因为该过程创建一个纯净的气氛更快,需要更少的氮气。氧水平降低后,热处理开始在有轻微超压的惰性气氛下。GLO退火炉的最高温度可能是1100℃,用于气氛热处理。如果需要的话,可以对圆柱形蒸馏器的前门进行加热。在水冷前门,气体在GLO内净化。它由插在前面的辐射罩进行预热。 The GLO is provided with a rear port for the expulsion of any gaseous by-products generated during the process. The GLO can be operated manually or with the use of an automated system. The furnace is available in sizes of 10 (mobile version), 40, 75, 120 and 260 litres. The retort is manufactured with temperature resistant steel alloy (1.4841). Other materials are available on request.

目录

没有这种产品的目录。

查看所有Carbolite Gero的目录