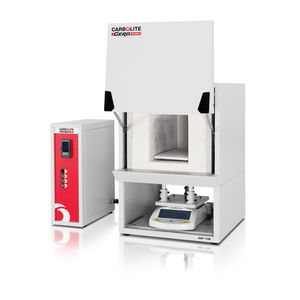

焊接炉HTF系列

chamber

电的

添加到收藏夹

比较这个产品

特征

- 功能

- 焊接

- 配置

- chamber

- 热源

- 电的

- 容量

-

分钟:64 L(16.9 GAL)

最大限度。:514 L(135.8 Gal)

- 最高温度

-

1,600°C,1,700°C,1,800°C(2,912°F)

描述

HTF工业炉范围最大的工作温度为1600°C,1700°C,或1800°C。所有型号都被钼硅化物元素加热。HTF工业炉可提供64,128,165,250,332和514升的可用体积。独立的过温保护装配为无人参与操作标准。热处理仅在空气中可能。可以提供额外的气体供应,带有手动阀和轮流管,这导致略微改变的大气,只抑制氧气水平,因为系统未被密封。结果,HTF是烧结陶瓷和氧化物陶瓷的理想选择。如果在烧结之前需要进行嗡嗡声,Carbolite Gero为HTF提供了逐步展示包。Deminding软件包包括预热空气,几个气体入口和后燃器的入口。预热空气在几个气体入口处对称吹扫到炉中,这通过进入空气改善低温下的温度均匀性和样品包络。 All gaseous by-products generated during the debinding process are combusted in an afterburner that is driven by propane gas and compressed air. On completion of debinding, the furnace temperature will increase to begin the sintering process. Application Examples annealing, ceramic injection moulding (CIM), debinding, debinding in air, degassing, drying, sintering, sintering in air, sublimation, synthesis, tempering Standard features 1600 °C, 1700 °C & 1800 °C maximum operating temperatures From 27 to 514 litre capacities Programmable 3216P1 controller Over-temperature protection High quality molybdenum disilicide heating elements

目录

此产品没有目录。

查看所有Carbolite Gero的目录

0/10产必威体育app官方下载品比较