辐射电加热器

涂层

添加到收藏夹”

这种产品比较

特征

- 电源

- 电

- 应用程序

- 涂层

描述

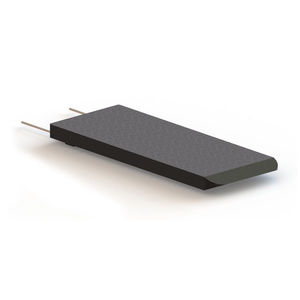

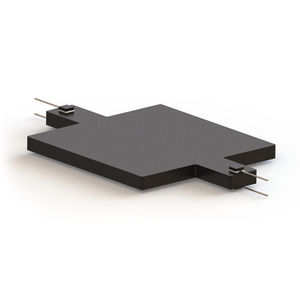

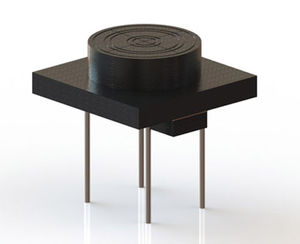

用氮化硅制成的辐射加热器通常是矩形的。我们的模具直径可达400毫米,可生产各种尺寸和批量尺寸。这些加热器有一个操作范围高达1 000°C的热区和接触区域的冷区。对于操作范围高达500°C的大型平板加热元件,可以提供无冷区。陶瓷材料的特殊性质和低质量允许快速的加热速度,均匀的温度分布和出色的控制精度。高发射率和宽发射光谱的热辐射使陶瓷材料,这是一个理想的辐射加热器,制造出来的几乎黑色氮化硅。在1 000°C时,辐射功率可达15 W/cm²。我们的内部设计使任何尺寸、配置或性能的修改简单方便。可包括温度测量孔。通过装配几个辐射加热器可以实现大的加热区域。 For reaching a uniform temperature distribution or desired temperature areas, the power input can be adjusted to the heat radiation. For operating in high vacuum or inert gas at up to 1 000 °C a purpose-built and well-tested pin contact can be supplied. Advantages Your advantages: You can generate the heat exactly at the spot where it is needed Fast heating rates reduce processing time and increase Your yield through shorter cycle times The inert and chemically resistant ceramic material avoids any contamination of your system Areas of application generating of hot air coating systems packaging machines evaporators preheating soldering systems vacuum technology

目录

这个产品没有目录。

请参阅巴赫电阻陶瓷有限公司的所有目录

0/10的必威体育app官方下载乘积比较