- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览

水平平衡机

垂直的

用于轴

自动的

添加到收藏夹

比较此产品

特征

- 方向

- 水平垂直

- 申请

- 用于轴

- 其他特征

- 自动,高准确性

描述

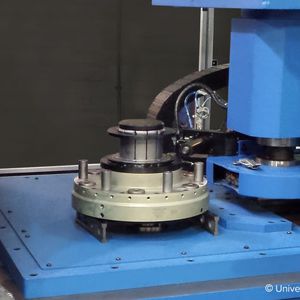

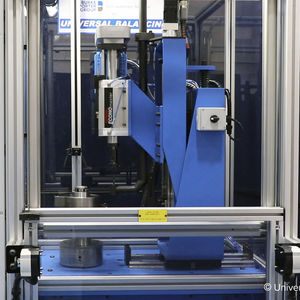

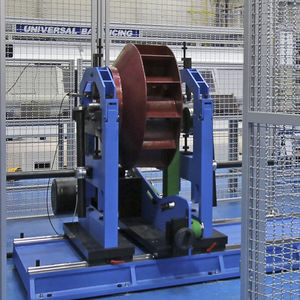

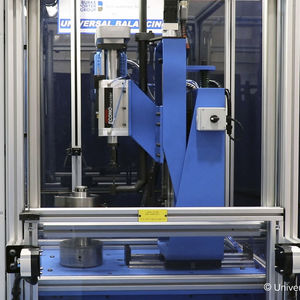

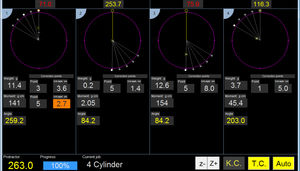

传输组件平衡机。用于变速箱,齿轮,轮毂和板的平衡机。自动单站或多站平衡机,专为大型生产线设计。智能过程中的反馈优化了生产吞吐量,并减少了拒绝。超高准确性。<10%部分公差的可重复性。行业领先的周期时间。总结我们的传输转子平衡机的范围可提供超高水平的准确性和可重复性,并超过行业流程能力要求。可以使用一系列水平和垂直平衡机,可容纳各种透射量组件,以一两平面的形式测量不平衡。机器通常具有自动钻或磨坊校正,并具有切割的启动检测和智能反馈。 This ensures quality unbalance correction, increased machine throughput and reduced rejects. Other integrated correction methods include punches, laser cutting, coupon welding as well as special rotor-specific methods. Our transmission component balancing machines for shafts, gears, hubs and plates, come with our industry leading UNI-64 Windows measuring system and easy to use Winbal balancing software. This includes error proofing of setups and operation, it also hosts features to improve cycle time, prompt routine maintenance checks and comprehensive industry 4.0 in-built diagnostics functionality. All our transmission component balancing machines have a small footprint as standard, are installed and commissioned in as little as 2 days and are built largely with industry standard components.