- 公司

- 必威体育app官方下载

- 目录

- 新闻和趋势

- 展览

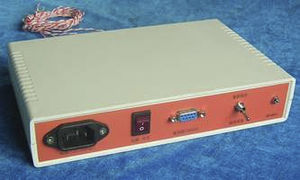

换流器电加热器AE-F600C

强制对流

添加到收藏夹”

这种产品比较

特征

- 电源

- 电

- 其他特征

- 强制对流

描述

SMTmax AE-F600C回流焊炉是一种高通量的热加工系统,其优异的热性能在印刷电路板的回流焊和半导体封装中都得到了广泛的认可。AE-F600C系统可以提供最优化的无铅处理,以达到最高的生产力和效率。AE-F600C回流炉的增强对流控制提供精确的加热,冷却和传热整个区域。AE-F600C回流炉包括3个顶部和3个底部加热区域。其最高温度可达400°C。该系统配有电脑控制和触摸屏。它的软件更新了简化的用户界面和令人难以置信的自校准能力。回流炉功耗为220V/ 60hz,正常运行功率约12.5KW,峰值功率约25KW;其外形尺寸为79 "X32" X50 ",包装尺寸为84"X32"X58 "。功能包括: Computerized independent Temperature Control system for Each Zone The SMTmax AE-F600C reflow oven's heating zone temperature are controlled by an accuracy of ±1°C closed loop controller in conjunction with a high-speed longer shaft designed blower adjacent to each heat source for maximum convection, ensure a ±2°C across the PCB assembly. The AE Series enhanced air flow design using centered slot with pressurized multi-hole technology to ensure a uniform hot air distribution, low-velocity, low-turbulence air flow to prevent component shift or disturbance, and provide heating zone do not interfere each others as well.

目录

没有这种产品的目录。

查看所有SMT MAX的目录