- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览会

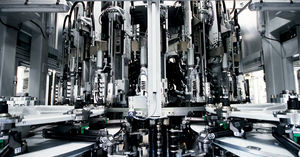

拉伸吹塑机Evoblow ph.

瓶子

对于饮料行业

加入最爱

比较这个产品

特征

- type

- 拉伸

- 完成的产品

- 瓶子

- 其他特征

- 对于饮料行业

描述

我们最可靠且具有成本高效的工业需求的解决方案,Sidel Matrix PH鼓风机为我们的优惠加热技术增加了新的尺寸。它结合了经过验证的pH过程的优势,采用模块化矩阵鼓风机来支持FHPC生产。Sidel’s preferential heating process controls material distribution for ideal container shape and wall thickness: - Heating modules equipped with infrared (IR) lamps - Selective heating via series of reflecting and non-reflecting zones on reflectors positioned opposite IR lamps - Constant preform rotation for repeatability of differentiated heating profile - Reliable, mechanical angular positioning of preform from preform-loading to bottle outfeed - Precisely targeted temperature profile for uniform material distribution Neck orientation When cap orientation is needed, an in-oven indexation system is available. This is a simple method of orienting the cap according to bottle shape, product pouring and label orientation. The machine configuration and output are customised accordingly and evaluated by Sidel experts.

目录

此产品没有目录。

查看所有Sidel的目录

0/10产必威体育app官方下载品比较