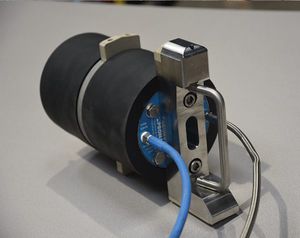

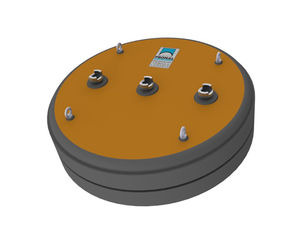

Inflatable shutterO series

flexible

for pipes

rubber

添加到收藏夹”

Compare this product

Characteristics

- Type

- inflatable, flexible

- Applications

- for pipes

- Material

- rubber, HDPE

- Other characteristics

- bypass

Description

“OHP & OPV” stoppers are capable of plugging all types of pipeline (Concrete, steel, HDPE, stainless steel…). They have been designed to withstand strong back pressures of up to 35 bars and even more on request. This is why they can be trusted to plug highly pressurized Nuclear, Onshore, Offshore & Gas pipelines for inspection, test, or maintenance operations. These pipe plugs systems also ensure the buoyancy of jackets or pipes. Other uses for our high-pressure stoppers include welding tests, valve repairs or replacements. We can propose the production of specific stoppers that include: • integrated flanges, • bypass, • specific coatings providing resistance against chemical, oil, or hydrocarbon contact, • an automatic inflation/deflation system, … ADVANTAGES Use •Optional “Bypass” system •Stopper can be used portably •Autonomous inflation system Safety •Capable of withstanding back-pressure of 35 bar or even greater upon request •Extremely durable •Tested without tools prior to delivery under equivalent conditions Handling •Easy to install and use •Rapid inflation •Reusable product DETAILED INFORMATION •Material: SBR / NPVC / EPDM depending on use •Technique: hot vulcanization in a vacuum autoclave •Range: oOPV with 3 bar back-pressure resistance oOHP 1 with 8 bar back-pressure resistance oOHP 2 with 15 bar back-pressure resistance and even more upon request •Dimensions: standard and tailor-made •Inflation: by air •Temperature resistance: -25°C/+100°C •Accessories: oBy-pass oCastor system oAutonomous inflation system

Catalogs

行业& Maintenance

19

Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.