特征

- 取向

- 旋转

- 类型

- 电

- 其他特征

- 精度

描述

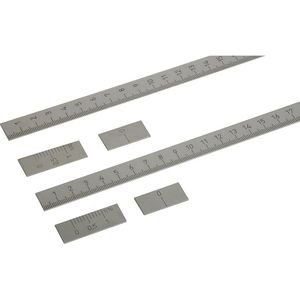

材料:底座和转台均为铝合金。空心轴为不锈钢。预加载蜗轮钢。爪式联轴器铝与聚氨酯联轴器蜘蛛。版本:铝合金阳极化。订货注意事项:本机附图电缆出线或控制单元位置。注:旋转定位台用于电动调整和定位任务。预加载蜗杆齿轮运行,实际上发挥自由。蜗杆轴的轴承提供了最大的径向旋转精度。电缆可以穿过空心轴的大孔。 The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (21088). The stepper motor with a resolution of 200 increments per rotation allows a single direction calculated positioning accuracy of 0.005 mm. The absolute single direction positioning accuracy is 0.01 mm. The system can be operated with a switch-on time of 100%. Can be combined with all other parts of the same size. Technical data: Transmission ratio: 55:1 Backlash: <0,1° Radial play: <0.02 mm Max. input speed: 600 rpm Max. duty cycle: 100 % Required input torque: 0.15 Nm Rigidity: see diagram Rotation: 360°, infinite Application temperature: +10 °C to +50 °C

视频

目录

直线导轨系统。位置指示器

156

页面

绿色大书2020年第2卷

1063

页面

其他norelm - Éléments标准mécaniques产品必威体育app官方下载

滑道滑道定位台线性导轨系统定位指示灯21000

0/10产必威体育app官方下载品比较