- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览

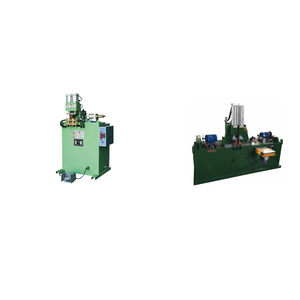

对接焊机爹妈- 800

plc控制

紧凑的

液压

添加到收藏夹

比较这个产品

特征

- 技术

- 屁股

- 运作模式

- plc控制

- 其他特征

- 紧凑、液压

描述

本机由机体、右、左、上、下、动、静臂(全部为铸钢件)、电极夹、横向驱动镦粗装置、液压系统、电控系统、焊接变压器系统等组成。1.采用美国赫斯公司的设计理念,采用液压系统控制夹头、熔体、镦头和熔体调整,保证了不同熔体系列的精度。卡箍采用高导电性硬铬锆铜制成,耐磨,易清洗。2.主变压器采用进口优质导电磁性钢板和电磁线材,双面无磁性铝头环氧树脂浇铸而成。具有真空浸渍、耐温、抗震、绝缘比高、可测泄漏小、节能、导电性好、输出功率大等优点。本机内置温度传感器,直壳式结构,铜管中间的铜板二次冷却。具有结构紧凑、冷却速度快、能耗低、效率高等特点,所有元器件均采用进口零部件(欧姆龙/PLC、变频器、按键、继电器指示灯等)。3.This machine is controlled by LIYANGPLC, Taiwan which have both manual and automatic program to ensure the reliability of the device. In automatic state, if we meet emergency, the welding process should be terminated forcibly, then after handling properly, reset the program and going on welding.