- 公司

- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览会

不锈钢化学蚀刻

个人

ISO 9001.

ISO 14001.

添加到收藏夹

比较这个产品

特征

- 经处理的材料

- 不锈钢

- 生产方法

- 个人

- 认证

- ISO 9001,ISO 14001

描述

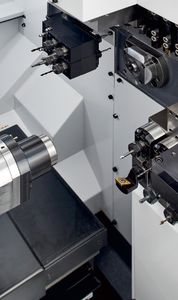

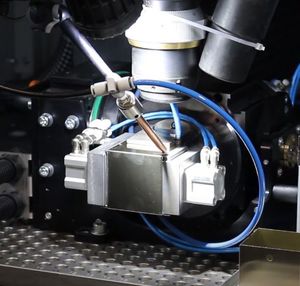

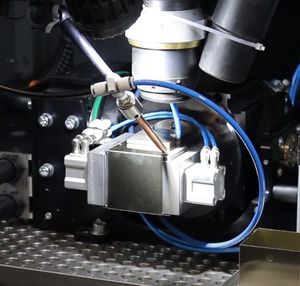

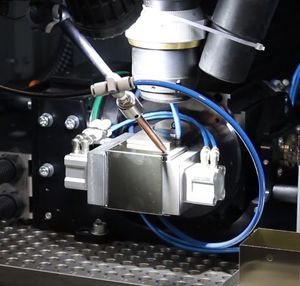

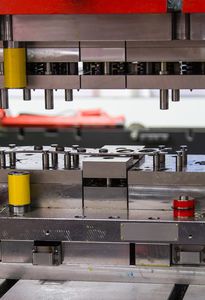

与我们的客户密切合作的照片化学蚀刻,多年来我们已经为照片化学蚀刻开发了创新的解决方案,从而推动了在技术上可能的限制。光学化学蚀刻工艺使得可以制造复杂的几何形状和传统机械板工作不能提供的公差的精密蚀刻部件。精密金属蚀刻技术是一种经济高达1.0毫米的材料冲压和激光切割的替代方案。这种微蚀刻技术可与各种材料一起使用,例如不锈钢,铜,镍银,黄铜和铝。PHOTO ETCHING ADVANTAGES Manufacture of complex geometrical shapes using many different raw materials The products can also be delivered in strips, sheets or coiled and ready for automatic installation at the customer’s location Entirely tension and burr free parts There are typically no tool costs associated with the photochemical machining Delivery can often take place within 2-3 weekdays DELIVERY OF PHOTO CHEMICAL ETCHING PARTS We can deliver prototypes within a few days as these do not require the use of fixed tools. Upon delivery, the parts can be packaged as agreed with the customer and can also be delivered on: Sheets Strips Rolls It is also possible to deliver the parts ready for installation at the customer’s location. The volume can vary from one individual piece to several million pieces.

目录

此产品不可用目录。

查看所有Mekoprint A / S的目录