- 公司

- 必威体育app官方下载

- 目录

- 新闻与趋势

- 展览会

模具基础

加入最爱

比较这个产品

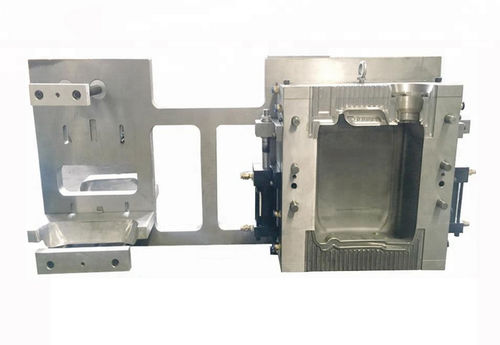

描述

特点:1,单腔为12个腔。2,体积为0.1L至120L。3.吹塑尺寸容量直径50厘米挤出吹塑模具挤出模具是用于挤出吹塑的模具,挤出吹塑仅适用于特殊机械:吹塑机。如您所知,我们是挤出吹塑机的专业制造商。我们还为我们的机器制成了这种挤出吹塑模具。挤出吹塑挤出吹塑成型是生产塑料瓶,罐子和水壶的几种吹塑方法之一。它是一种常见的吹塑技术,用于处理许多不同的塑料,包括HDPE,PVC,PC,PP和PETG - 以及需要多层技术的瓶子非常常见(具有特殊氧气/防潮性要求的瓶子,以提高产品兼容性&稳定)。EBM工艺挤出吹塑的步骤是最简单的吹塑类型。从挤出机中掉下一个称为型坯的塑料材料的热管,并在水冷模具中捕获。 Once the molds are closed, air is injected through the top or the neck of the container; just as if one were blowing up a balloon. When the hot plastic material is blown up and touches the walls of the mold the material “freezes” and the container now maintains its rigid shape. For colored bottles, colorants are often fed into the extruder at a controlled rate and mixed with the resin as they are being melted. If barrier and adhesive layers are required, they are fed separately and combined in a co-extrusion head

视频

目录

此产品没有目录。

查看东莞市金骏机械有限公司的目录

0/10产必威体育app官方下载品比较