- 必威体育app官方下载

- 目录

- 新闻和趋势

- 展览

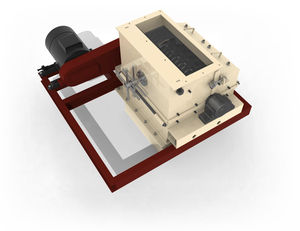

制粒机

添加到收藏夹”

这种产品比较

描述

该机是一种用于熔融玻璃连续造粒的设备。滚筒安装在造粒机支承架上的两对驱动辊上,与轴向辊在纵向上锁定。滚筒内表面有一个螺旋,用来移动熔化的或颗粒状的玻璃。由于玻璃颗粒只在滚筒内表面滚动,其磨料磨损很低,而机器的耐用性和可靠性都很高。水位由滚筒设计确定。进气鼓一侧装有环形,另一侧为锥形。机器向进水或出水侧倾斜,影响冷却水溢出。滚筒由电动齿轮箱通过链条和摩擦传动驱动。熔化的玻璃被凿入鼓内。在滚筒中造粒的时间可以根据驱动转数设定。 The cooling water is either chuted in the drum together with the melted glass, or it is fed separately through the drum inlet or outlet. An electric switchboard with switches, circuit breakers and frequency changer of revolutions makes a part of the machine. Capacity of the granulator depends on customer’s requirements.

目录

这个产品没有目录。

看看波西米亚机器的所有目录

相关搜索

0/10的必威体育app官方下载乘积比较